Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

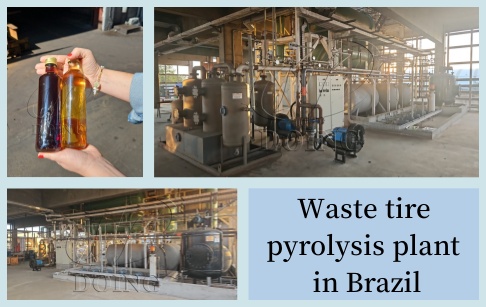

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

What's the Price to Install a Pyrolysis Stove in the Philippines?

2025-05-15 / Industry News / Leave Message / Chat Online

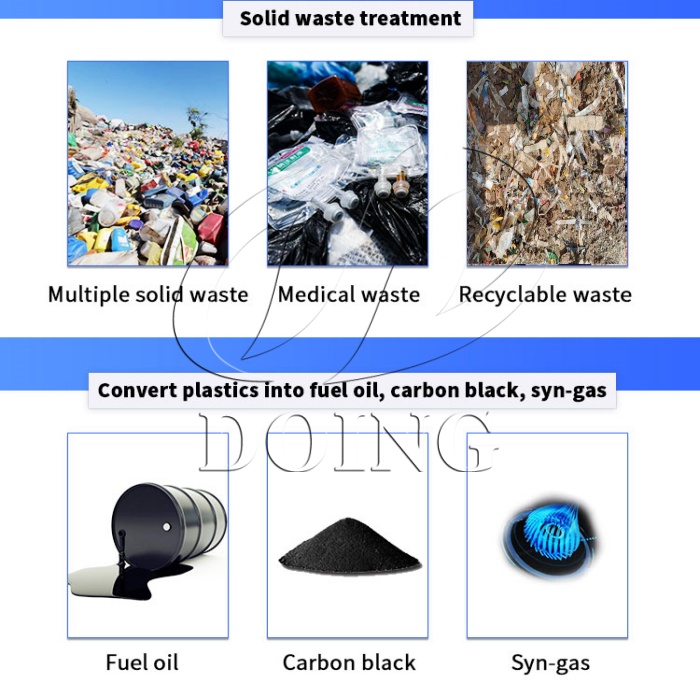

In recent years, as environmental awareness and renewable energy demands continue to rise, pyrolysis stoves have garnered widespread attention. In the Philippines, waste materials such as waste tires, plastics, oil sludge, and rubber can be transformed into fuel oil, carbon black, and steel wire (for tires) through pyrolysis stoves. These products hold significant market value. For businesses and investors looking to install pyrolysis stoves in the Philippines, understanding the associated costs is a critical first step.

DOING waste pyrolysis stove

Equipment Capacity: Determining the Scale of Investment

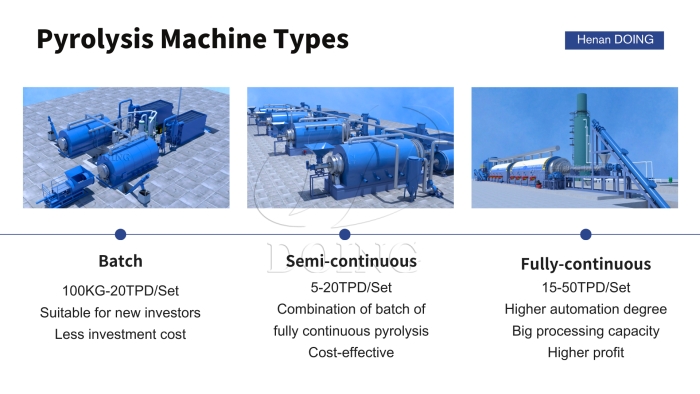

Pyrolysis stoves vary in processing capacity, with DOING Company offering options ranging from 100 kilograms to 50 tons per day. The selection of equipment capacity depends on daily waste collection volume and budget considerations. Smaller-scale equipment may suffice for areas with limited waste supply, while larger-scale equipment is better suited for regions with abundant waste resources. However, larger equipment typically comes with higher costs. When determining equipment capacity, it is essential to conduct a thorough market survey to assess local waste generation and collection capabilities, ensuring that the equipment's processing capacity aligns with actual needs to avoid resource idleness or insufficient processing capacity.

DOING pyrolysis stove types and capacities

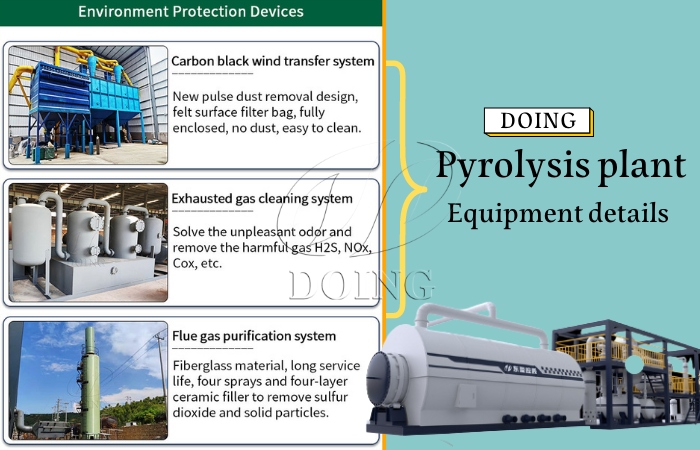

Equipment Configuration: Balancing Performance and Cost

In addition to the basic standard configuration of a pyrolysis stove, DOING has taken into account that customers may be concerned about the safety, production efficiency and environmental protection standards during the first operation of the pyrolysis stove. Therefore, some optional configurations have also been developed. Such as safety configuration: vacuum device; Environmental protection configuration: exhaust gas purification device and smoke dust removal device; Automation configuration: automatic feeder, automatic wire drawing machine and carbon black screw conveyor, etc. You can choose different optional configurations based on whether the local environmental control is strict, whether the local labor cost is high, and whether your budget is high. The higher the configuration, the higher the safety performance of the equipment, the more environmentally friendly the operation, the higher the degree of automation, and the less effort it takes, but the overall price of the equipment will be higher.

DOING pyrolysis stove equipment details

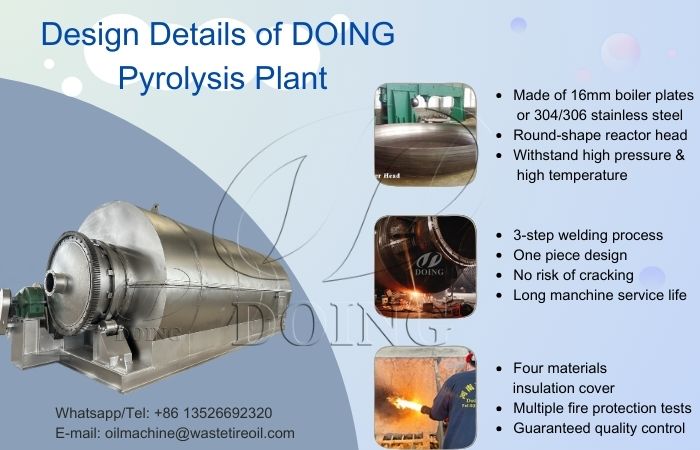

Equipment Design: The Impact of Innovation on Cost

In order to enhance the operational efficiency of the waste tire pyrolysis device and improve production efficiency, DOING has been constantly researching and developing new design equipment. We will also improve the material and operational performance of the equipment based on the feedback from the actual operation experience of our customers, making the operation of the equipment simpler and more efficient, more durable and extending its service life. However, the development of new equipment and the use of high-quality materials inevitably lead to higher costs. While new equipment offers superior performance and long-term value, it comes with a higher initial investment. For investors with limited budgets, older equipment designs may serve as a transitional option. As profits accumulate, they can gradually upgrade to newer equipment.

Design details of DOING pyrolysis stove

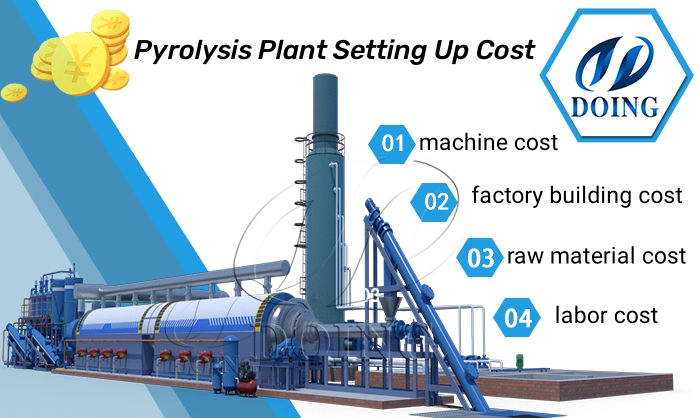

Additional Costs and Considerations for Installation:

The price to install a pyrolysis stove in the Philippines also includes other costs such as land preparation and construction for the plant site, which involves site selection, land acquisition, and building the necessary infrastructure. Labor costs for hiring skilled and unskilled workers are another significant factor, including wages, training, and benefits. Additionally, the cost of raw material acquisition and transportation must be considered, as well as ongoing operational expenses like utilities and maintenance. These factors collectively influence the total investment required for setting up a pyrolysis stove facility in the Philippines.

Pyrolysis stove setting up cost

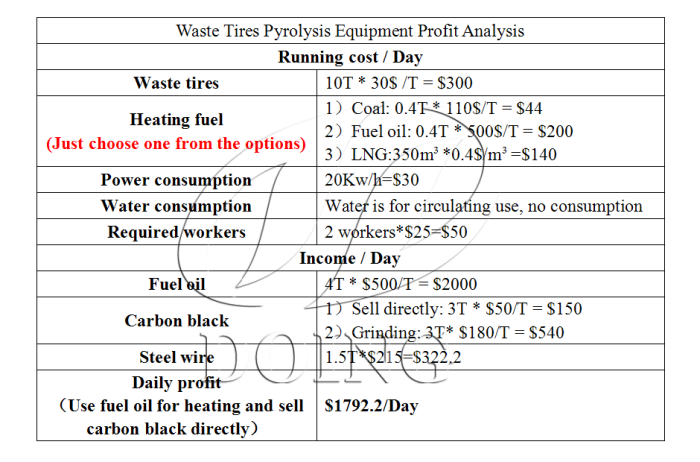

Waste tire pyrolysis stove profit analysis

The cost of installing pyrolysis stoves in the Philippines is influenced by multiple factors, including equipment capacity, configuration, design type, market environment, and policy conditions. The overall cost estimate ranges from approximately US$30,000 to US$1 million. Investors should comprehensively consider these factors to determine the most suitable investment plan based on their actual circumstances. This year marks the 14th anniversary of DOING's establishment. To express gratitude for the continuous support from our customers, the company's leadership has set a considerable discount on the pricing of each device. If you are interested in installing pyrolysis stoves in the Philippines and wish to learn more about specific costs, please feel free to contact DOING Company. We will provide detailed quotations and professional support to help you navigate the waste pyrolysis business.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.